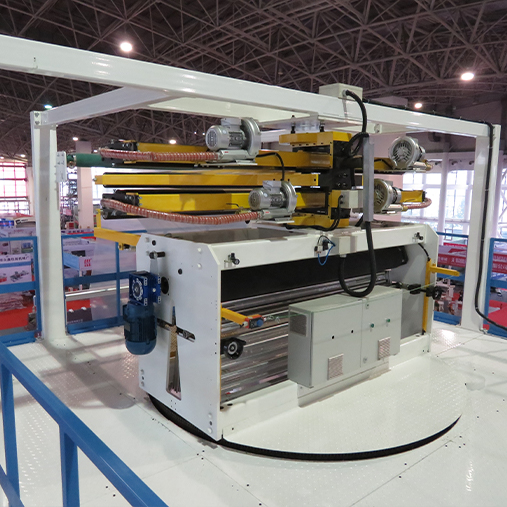

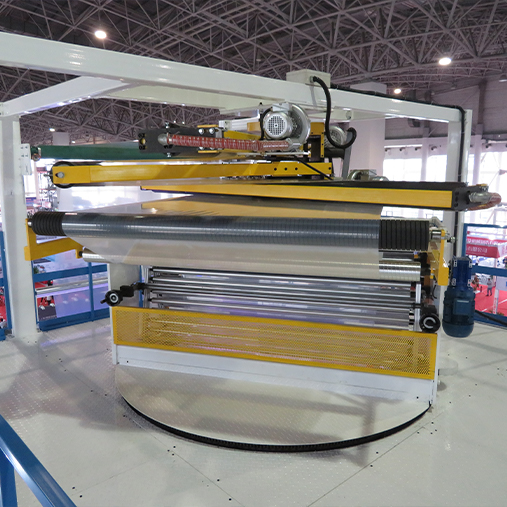

鐵嶺Horizontal rotary traction device

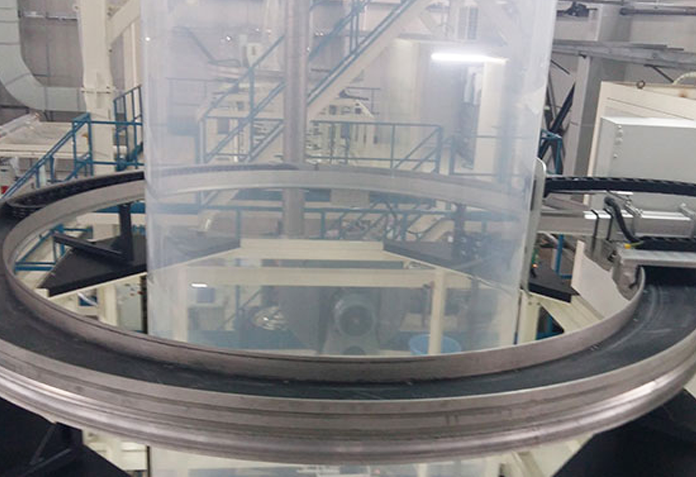

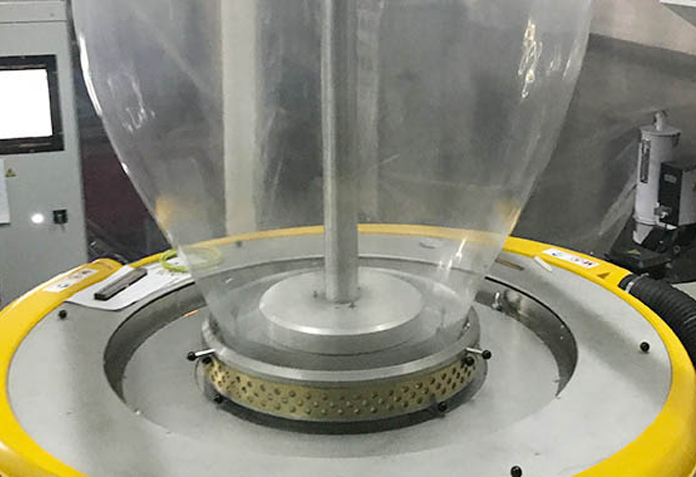

Horizontal rotary traction adopts horizontal ±360°swinging rotation, with constant film linear speed, scientific and reasonable structure, energy-saving and easy maintenance. It replaces the rotary die head, simplifies the die head structure, and completely solves a series of problems such as long rotary die head runners, difficult melt sealing, easy material leakage, uneven heating, difficult maintenance, and large film tolerance. At the same time, it simplifies the difficulty of formulating materials and controlling production process for multi-layer co-extruded products. If combined with the film bubble internal cooling system, it can produce film products with higher transparency and better physical properties.

The film produced by using this device has better flatness, precise film roll cylindricity, and film rolls without small or large heads, so that the film thickness deviation caused by die head, wind ring and tower is evenly distributed on the film rolls, which ensures high quality of film roll forming in winders and meets the requirements of high precision and high speed printing lamination.

Home

Home Products

Products Telephone

Telephone Message

Message